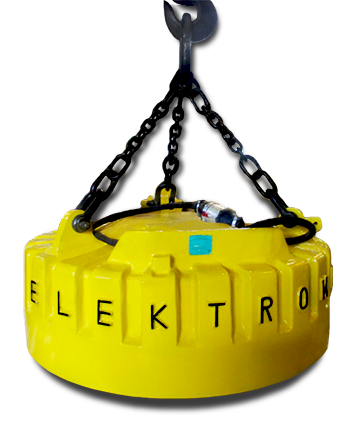

ELEKTROMAG DEVICES P LTD.

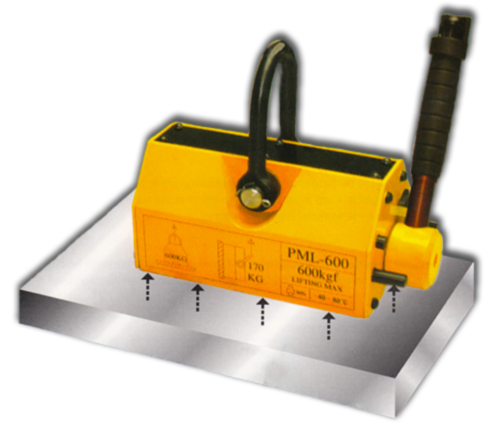

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to ELEKTROMAG DEVICES P LTD.

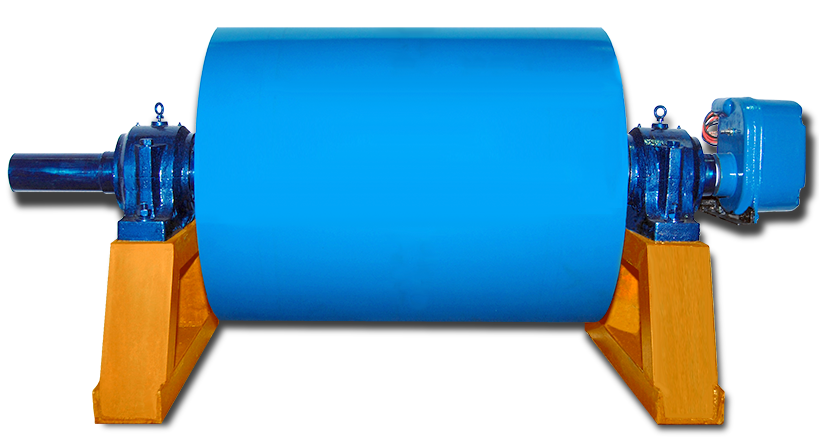

Magnetic Pulley Electromagnetic

ELEKTROMAG Electro Magnetic Pulleys have a magnet system of disk-shaped pole bodies with inserted coils. The pole bodies are made from steel of high permeability. The coils are normally made of Aluminium, rated for class ‘H’ insulation, however, Copper-coils can also be supplied. Pole bodies and coil form a complete unit. All coil connections are led to a terminal box on the face of the outer pole from where they are connected to sliprings through the shaft.

Non-magnetic coil covers are provided between the pole bodies in such a manner that protection against dust and water is guaranteed. The rings made of non-magnetic material at the two outer pole bodies guarantee a good support of the conveyor belt over the entire pulley width.

The electro-magnetic pulleys are placed in two generously dimensioned pedestals with self-aligning ball or roller bearings. The surfaces of the Electro-Magnetic Pulley are turned cylindrically.

D.C. is fed to the Electro-Magnetic Pulleys via two slip rings. The sliding contact device is enclosed in a dustproof housing and contains the necessary carbon brushes.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.